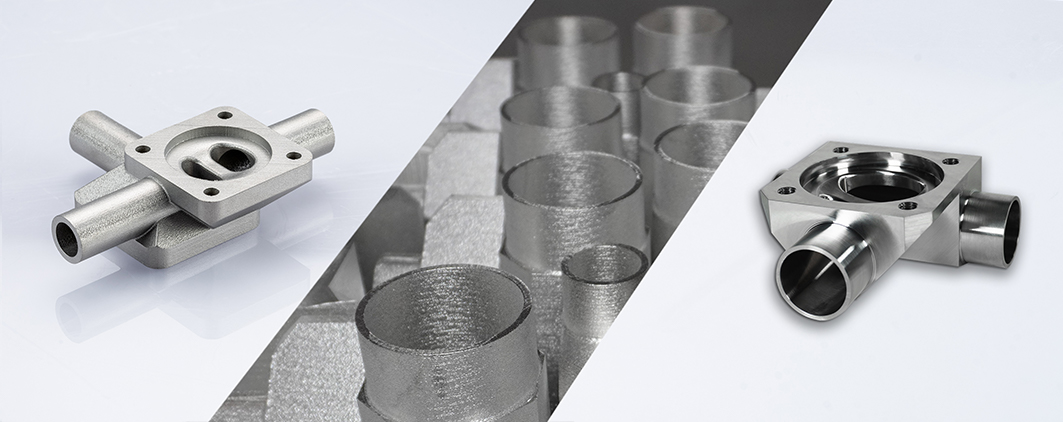

Benefits of additive manufacturing

-

Greater availability

Additive manufacturing has the advantage of a better material availability, as the process enables the production of the different valve body parts from only one raw material, metal powder. This leads to shorter delivery times for the customer.

-

High flexibility

Additive manufacturing offers a better planning and design flexibility. Since there are no bounds to the shape of the forged materials, new possibilities for design open up, and with shorter planning lead times. This means shorter project periods for our customers.

-

Higher material homogeneity

Raw components made by additive manufacturing have better material homogeneity than forged components.

-

Unaltered quality

The products go through the same quality checks as the conventionally manufactured parts and each batch produced is subject to dedicated testing. The physical parameters of all melted parts are seamlessly monitored and witnessed.

-

Light and space-efficient

In the additive manufacturing process, no forged material is used; instead, material is only built up where it is needed. This results in much lighter diaphragm valve bodies.

-

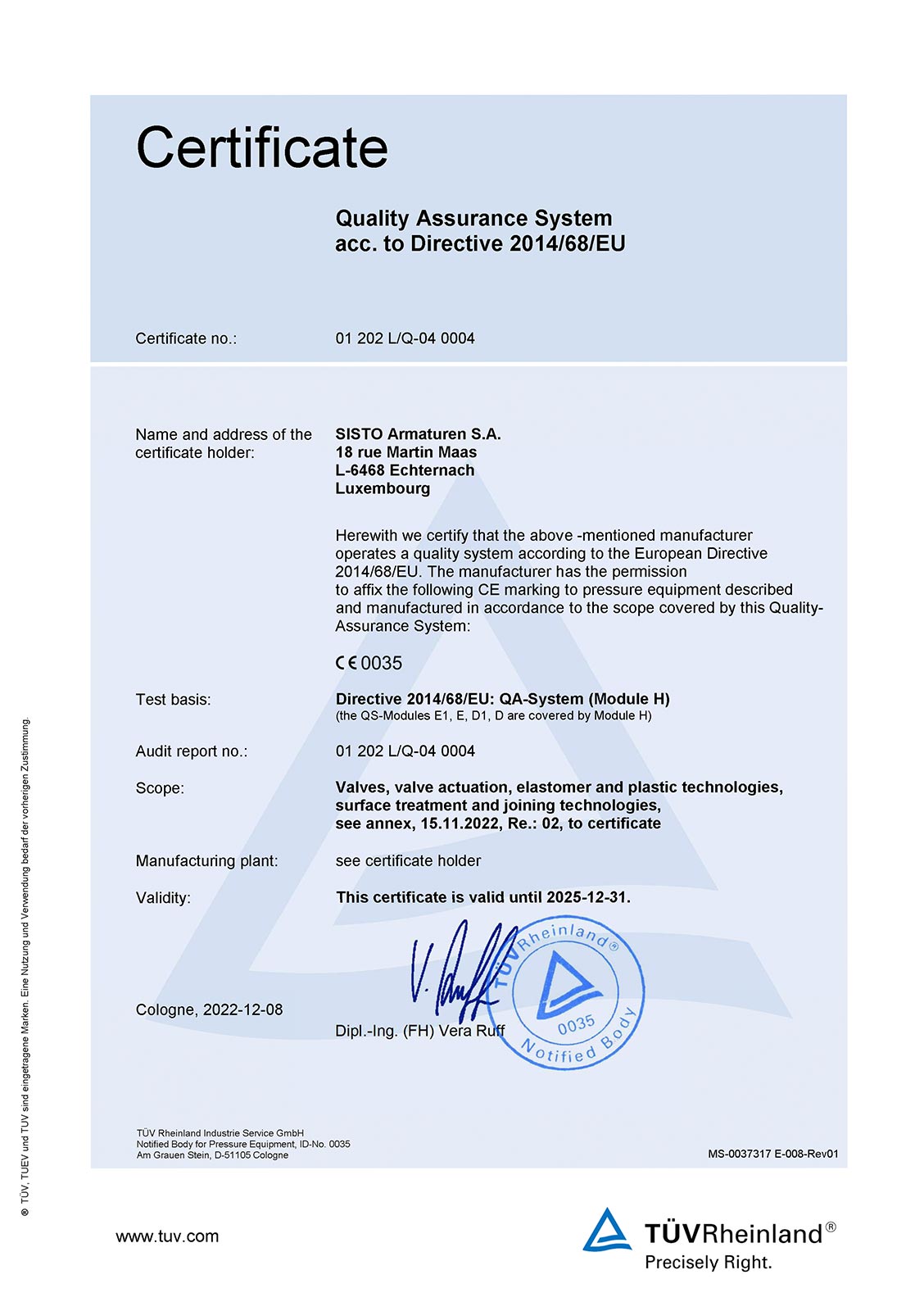

Compliant with Pressure Equipment Directive

The suitability of the 3D print materials was tested and documented by SISTO, with the involvement of the notified body TÜV Rheinland. The additively manufactured diaphragm valves thus meet the requirements of the European Pressure Equipment Directive (PED) 2014/68/EU.

How does SISTO ensure the same quality standards for additively manufactured diaphragm valves?

Compliance of the materials designed by additive manufacturing has been tested and documented by SISTO, through the German certification body TÜV. The additively manufactured diaphragm valves thus fulfil all the required standards for use in the pharmaceutical and biotech industry, as well as of the European Pressure Equipment Directive (PED) 2014/68/EU.

The quality is the same as for comparable forged diaphragm valve components.

The production is TÜV certified. The physical parameters of all melted parts are seamlessly monitored and substantiated.

Head of Production

What does the future hold?

Additive manufacturing offers a number of advantages over conventional manufacturing processes and will gain in importance in the future. The demand for customised solutions will also steadily increase. SISTO is well prepared for this future, as we have already implemented many of the processes required for this through the design and manufacture of customised multi-port valves.

One thing is certain: SISTO will continue to invest in research and drive forward the further development of additive manufacturing for diaphragm valves.

Additive manufacturing technology will develop considerably in the next few years to become faster and more efficient.

Managing Director SISTO Armaturen S.A.

We were fascinated by the new design possibilities and the idea of only building up material where it is needed.

Head of Design and Development